"Kailand09" (kailand09)

"Kailand09" (kailand09)

09/09/2014 at 19:25 • Filed to: None

1

1

22

22

"Kailand09" (kailand09)

"Kailand09" (kailand09)

09/09/2014 at 19:25 • Filed to: None |  1 1

|  22 22 |

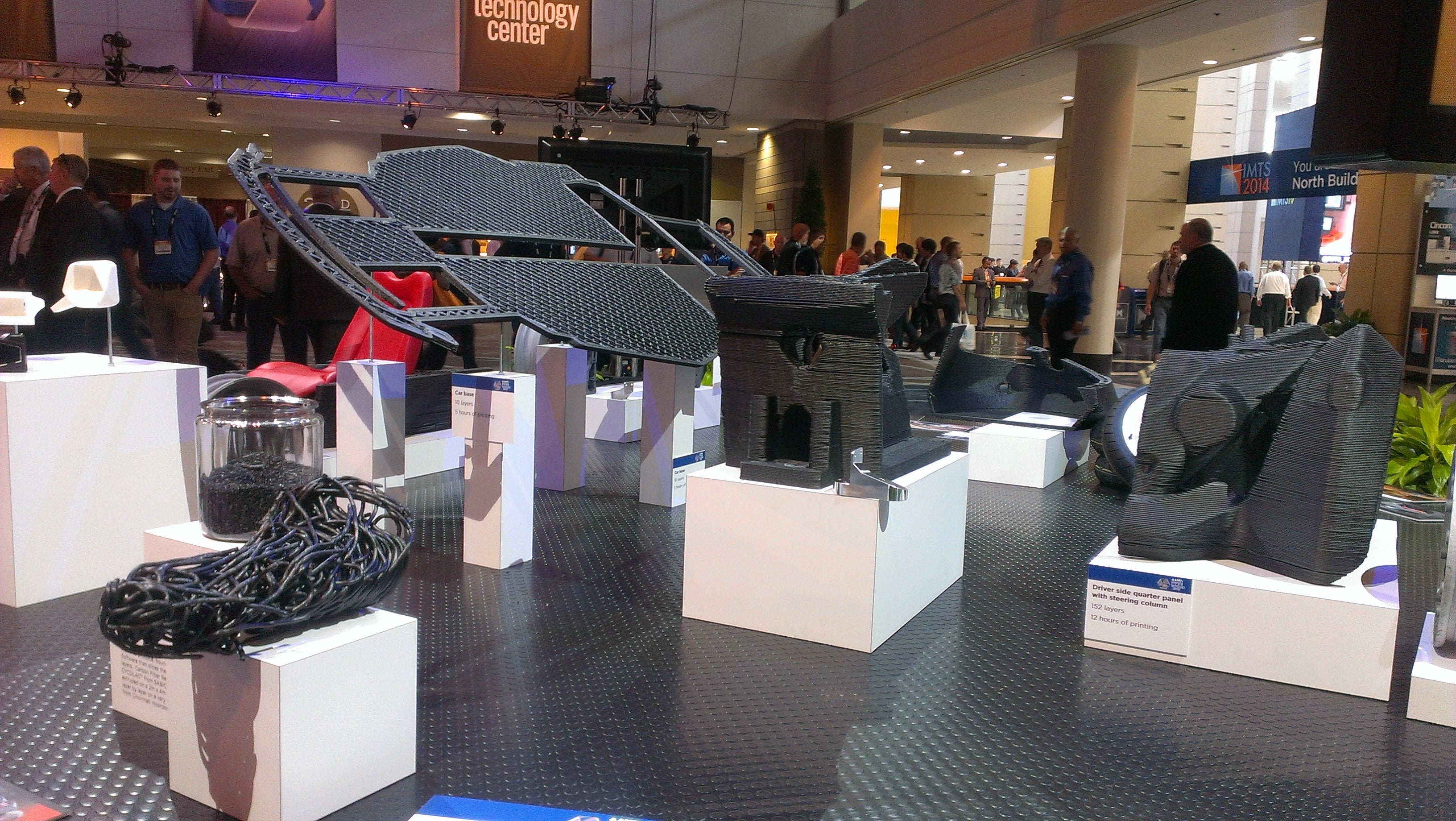

At IMTS, Local Motors is 3D printing most of a car, as you all likely know. I thought I'd supply some extra information and some terrible potato pictures.

As I understand it (correct me if I'm wrong), they are first 3D printing it with some sort of Carbon material in a giant 3D printer. You can see it pictured here:

The kind manufacturer has used a window to allow us to see this process while still staying nice and safe, though it has also caused the awesome glare you see. Apologies for that. What's happening here is the printing process, and the process leading to why you can see each individual layer in the parts. The raw material starts in a sand like consistency in a hopper, and is fed down through the white pipe. The head spits it out, and the whole thing is moving around to whatever coordinates the CAD program gives it.

It is then carried over to the giant CNC machine to be machined down, smoothing out some surfacing and making holes where needed, etc. This process apparently wasn't well planned out, according to an engineer I talked to on the side. Local Motors seemingly didn't realize you can't simply carry that body through the small door, and they had to solve the logistical issue. More importantly, though, their drawing had no origin, meaning the CNC didn't have a coordinate to start at and dimension everything from.

No matter, though, they got it sorted. The CNC action is pictured here, again with some awesome reflection:

You can see in the last picture where the machining head is doing its thing (at the left), and all the black stuff on the ground is waste material that was milled off during the process.

That's as far as it had gotten while I was there, hope ya'll enjoyed seeing the progress. It should be a very cool and revolutionary concept, and I think Local Motors is doing great work to push some boundaries in the auto industry.

Sam

> Kailand09

Sam

> Kailand09

09/09/2014 at 19:33 |

|

Cool! I know that Koenigsegg 3D prints some of their small parts, like mirrors and trim pieces. A (mostly) whole car though? We're living in the future, people, and the future is awesome.

Kailand09

> Sam

Kailand09

> Sam

09/09/2014 at 19:36 |

|

I bet one could make a fairly strong tub with the 3D printing. I'm interested to see how this thing turns out.

Also, yeah Koenigsegg is one of my favorite manufacturers. They do a lot of cool innovation.

Sam

> Kailand09

Sam

> Kailand09

09/09/2014 at 19:43 |

|

You really could. 3D printers already utilise a honeycomb structure, which is how supercars (like Koenigseggs) are so light, strong, and safe.

Have you watched /Drive's Inside Koenigsegg series? That's how I learned about their ventures into 3D printing.

Kailand09

> Sam

Kailand09

> Sam

09/09/2014 at 19:44 |

|

I've seen quite a few of their episodes.

In fact... I wonder if I should try to get work to buy a 3D printer for these reasons... haha

Sam

> Kailand09

Sam

> Kailand09

09/09/2014 at 19:50 |

|

If they do any prototyping or machining using CAD it'd be great value. You get to see exactly what the finished product will look like, before you waste money on the actual material.

tromoly

> Kailand09

tromoly

> Kailand09

09/09/2014 at 19:55 |

|

Other people are printing "carbon", just not in the automotive world.

However, the thing that makes carbon fiber awesome is the strength of the fibers in their orientations. By extruding there is no way to have fibers of any meaningful length, making it more like a Carbon Reinforced Plastic than actually carbon fiber.

Kailand09

> Sam

Kailand09

> Sam

09/09/2014 at 19:59 |

|

yeah, we do some. Would definitely be very nice.

Kailand09

> tromoly

Kailand09

> tromoly

09/09/2014 at 20:00 |

|

Yeah this is true. It's actually a downfall to strength I was thinking of, because it certainly is not carbon fiber, which is why I didn't call it that.

Still, some plastics can be quite strong, more-so when reinforced. With their density, you can use much thicker walls than used in metals, so it wouldn't be impossible to achieve a useful strength.

Sam

> Kailand09

Sam

> Kailand09

09/09/2014 at 20:31 |

|

Pass it by your boss. If you do get one, download some 1:48 models of cars and print them out!

Here's a link to one of the best small scale printers on the market (in case you didn't notice, I'm a 3D printing nerd. Gonna get a printer in the next month or so):

https://www.ultimaker.com/pages/our-prin…

mcseanerson

> Kailand09

mcseanerson

> Kailand09

09/09/2014 at 20:36 |

|

Hey I think my company is at that show right now. If you get a chance you can stop by Telesis and see where VINs and 2D codes on auto parts come from.

Kailand09

> mcseanerson

Kailand09

> mcseanerson

09/09/2014 at 20:51 |

|

Bummer, as I had only one day and it is up already :(

Was quick, as I wasn't alone. Wish I woulda posted earlier to hear about that though.

Kailand09

> Sam

Kailand09

> Sam

09/09/2014 at 20:52 |

|

that's awesome. Honestly, I'd love to grab a 3D printer myself and rapid prototype for companies.

Sam

> Kailand09

Sam

> Kailand09

09/09/2014 at 20:54 |

|

Do it when you get a little extra cash. This is a better, cheaper option if you're just getting into it and don't need super high precision.

http://www.robo3dprinter.com/products/robo-…

Kailand09

> Sam

Kailand09

> Sam

09/09/2014 at 20:58 |

|

Hmm... this is interesting. Only thing is I would like a CAD software suite if I started doing freelance and printing... could be a really good investment. Do you plan to sell prototyping services?

Also, what makes the other one better? Just the tolerances it can hold?.1" is kinda huge in terms of tolerance, though.

Sam

> Kailand09

Sam

> Kailand09

09/09/2014 at 21:11 |

|

Mostly it's fewer errors and higher quality parts. The Robo3D usually needs some fine tuning before it is really up to par with the Ultimaker. The good thing about 3D printers is that they can print their own upgrades. Here is a video from the guy that inspired me to get in to 3D printing. He's a bit silly, but you can see the capabilities of one of the Robo3D. (Don't worry about the thumbnail, he isn't PewDiePie)

As far as selling services goes, these printers take quite a long time to do prints (some can take up to 15 or more hours if they're large prints) so it would only be really efficient if I had several machines running at the same time. Industrial level machines will often have several print heads going at once and can move at much higher speed.

Also if you're a student (or want to claim you're a student), you can get Autodesk software for free: http://www.autodesk.com/education/free…

Kailand09

> Sam

Kailand09

> Sam

09/09/2014 at 21:18 |

|

Very informative. I'll have to keep all this in the back of my head. Though I can already think of things that would be nice to 3D print on my current project... haha

Sam

> Kailand09

Sam

> Kailand09

09/09/2014 at 21:20 |

|

Didn't think you'd learn this much about 3D printing on Oppo, did ya? :)

Kailand09

> Sam

Kailand09

> Sam

09/09/2014 at 21:25 |

|

Lol no actually. Though my interests are piqued

Sam

> Kailand09

Sam

> Kailand09

09/09/2014 at 21:28 |

|

Haha, well if you or your company starts 3D printing, let me know!

Kailand09

> Sam

Kailand09

> Sam

09/09/2014 at 21:59 |

|

will do!

katester

> Kailand09

katester

> Kailand09

09/10/2014 at 00:24 |

|

There's a sweet timelapse of the car printing:

Kailand09

> katester

Kailand09

> katester

09/10/2014 at 06:11 |

|

Pretty awesome, thanks for the link! I can't wait to see it finished up.